Glick are designers and manufacturers of luxury gift wrappings and accessories based in West Yorkshire. Hazel 4D have been supporting Glick with sustainable solutions to reduce their material waste, increase efficiency and improve the presentation of how their products are packaged to meet their brand goals.

Glick faced multiple packaging challenges, particularly reducing plastic waste and improving recycling practices for tape and cardboard. With a diverse range of products varying in size and shape, they required tailored packaging solutions to ensure sustainability and efficiency.

Overuse of cardboard boxes was another significant issue, compounded by the need for appropriately corrugated cartons that could be quickly assembled to improve throughput. Additionally, packaging for wrapping paper rolls posed unique difficulties, as selecting the right size and thickness of boxes was essential.

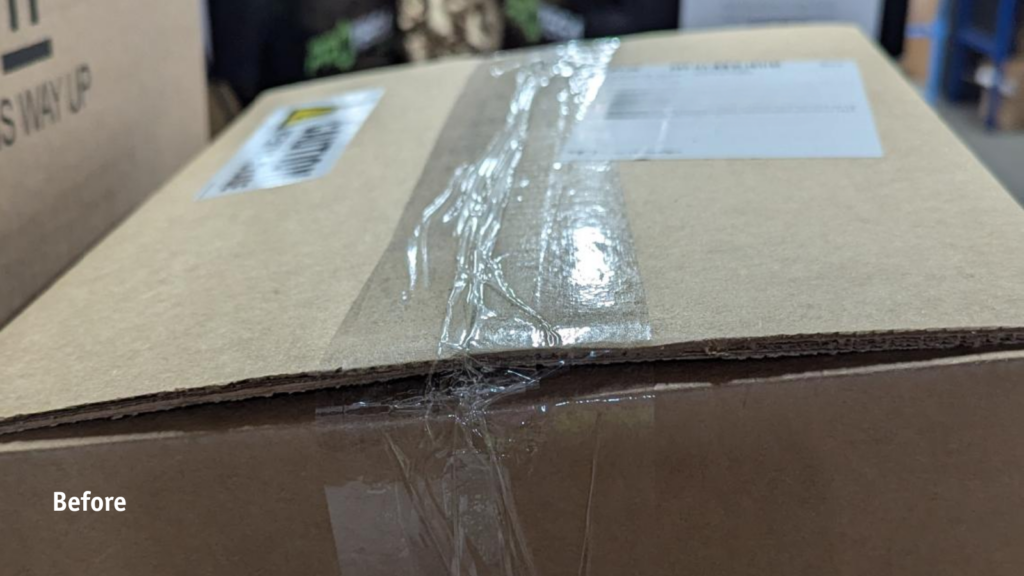

Products often underwent multiple handling stages during transit, which sometimes affected the integrity of the packaging. This resulted in items arriving in a condition that did not reflect the high standards set at Glick’s warehouse, impacting customer satisfaction and brand perception.

Hazel 4D, in collaboration with Glick’s Distribution Manager Paul Clayton, initially provided packaging consumables such as cardboard boxes and equipment. Leveraging their expertise, Hazel 4D expanded their role to deliver sustainable, efficient packaging solutions tailored to Glick’s needs.

Key measures included replacing plastic mailbags with paper-based alternatives, reducing reliance on plastic. To address tape usage, Hazel 4D introduced branded gummed paper tape and LP1 Electric Gummed Paper Tape Dispensers. This upgrade streamlined Glick’s taping process. Just one strip on each side of a box is needed, significantly reducing tape consumption and costs while enhancing the packaging’s professional appearance.

To optimise box usage, Hazel 4D conducted site visits and rigorous testing, such as drop tests and product capacity assessments. These evaluations ensured boxes met the required size, thickness, and durability for Glick’s diverse products. As a result, fewer boxes are now used, and packaging stability has vastly improved.

Hazel 4D’s solutions have transformed Glick’s packaging process. Reduced waste, enhanced efficiency, and a focus on presentation have minimised returns and damages while boosting customer satisfaction. Products now arrive in pristine condition, safeguarding Glick’s reputation for luxury and quality.

“The feedback from our customers on the presentation of the boxes has been great. Our returns are minimal, our damages are minimal because our boxes are a lot more solid. Anything around packaging consumables and packing solutions, I’d recommend Hazel 4D 100%.”

Paul Clayton – Distribution Manager at Glick