Yorkshire based packaging specialists Hazel 4D have been going the extra mile to meet urgent customer requirements during this unusual time.

Hazel 4D provides innovative packaging products that help their customers save time, money, and the planet. As a packaging specialist, the firm understands the importance of protecting customers’ goods in an efficient manner and does so by offering a completely unique service.

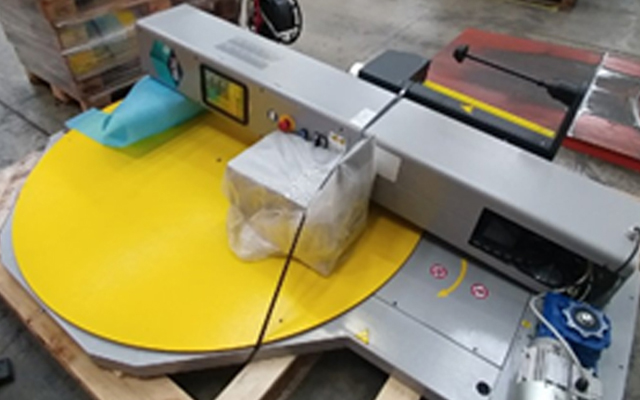

The Technical team at Hazel 4D have been preparing machinery in-house and delivering it ready-to-run with training and support via video conference for customers end-users. This means the equipment can ‘plug and play’ once it arrives.

In addition to this, the company, supported by their Italian supply partners, Atlanta Stretch Spa, has been working at a very rapid pace and recently managed to get machinery commissioned, delivered and installed within 24 hours. Their customer in Telford had a huge production backlog that was meeting a bottleneck in the dispatch department. The Atlanta Synthex pallet wrapping machine increased productivity by over 50%, helping the customer fulfil its export contracts.

In a recent LinkedIn post from Hazel, they said:

The Hazel 4D team leapt on the enquiry in the morning, had the machine set up to the customers optimised settings in-house by our technical experts and the customer had it delivered and running the next day.