Take the first step in packaging automation.

Significantly quicker than taping boxes manually, semi-automatic case sealers have a small footprint and can be easily integrated into existing production lines and used with a variety of box sizes and tape specifications.

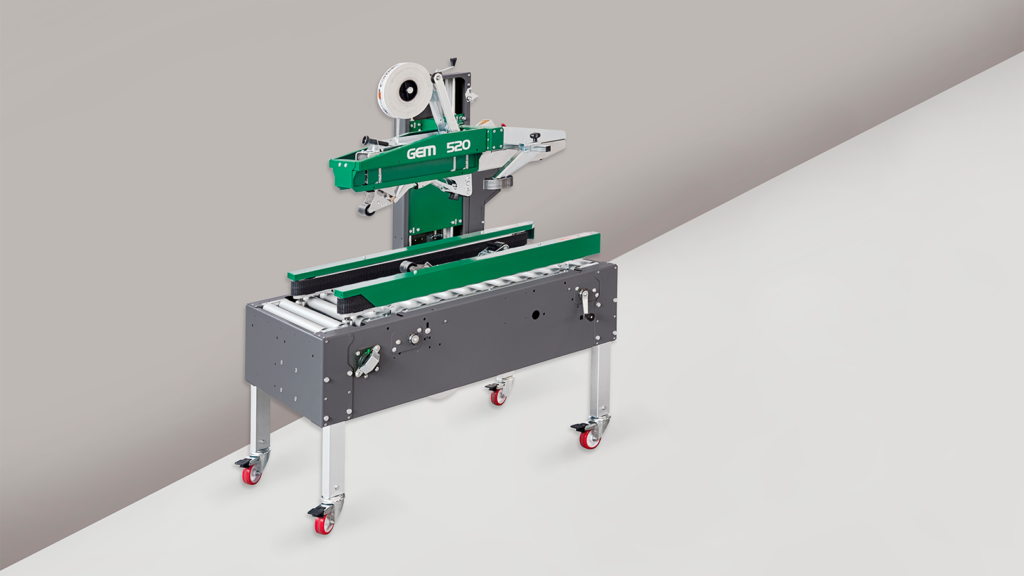

This simple semi-automatic uniform case sealer seals the top and bottom of fixed format cartons. With uniform machines, the height and width settings can be easily adjusted to fit the size of your cartons using the handle. This allows the machines to be used by non-specialist operators. Use with adhesive plastic tape or self-adhesive paper tape in 25 – 100 mm widths.

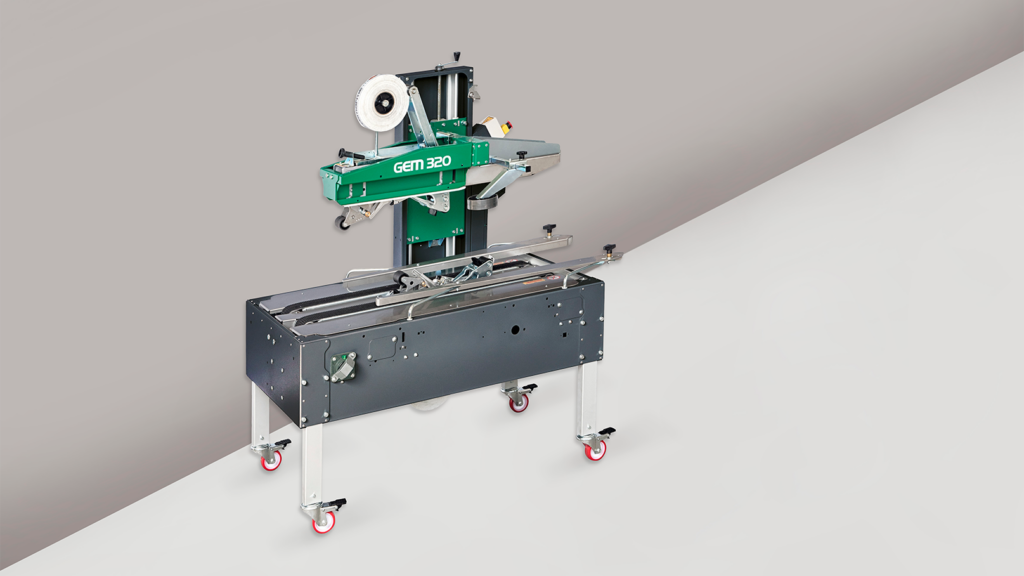

This semi-automatic uniform case sealer seals the top and bottom of fixed format cartons. Particularly good for sealing tall, narrow boxes or unusually shaped cartons. Use with adhesive plastic tape or self-adhesive paper tape in 25 – 100 mm widths.

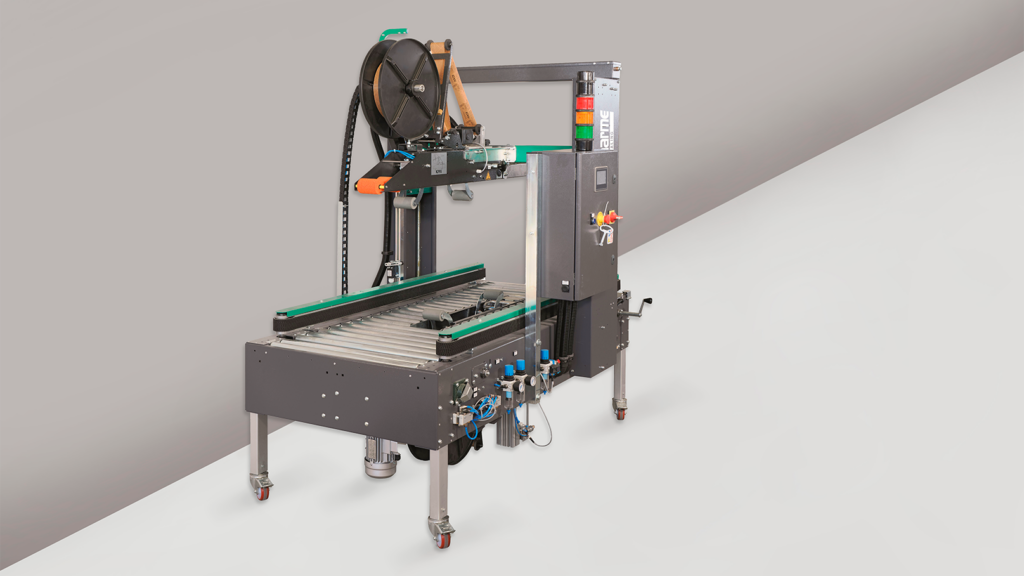

Random case sealers can seal boxes of various sizes as the height and width settings automatically adjust to fit the dimensions of each carton, with the same minimum and maximum dimensions as the uniform tape sealers. Auto flap closer model is available for each machine configuration.

Both automatic and semi-automatic ranges are available.

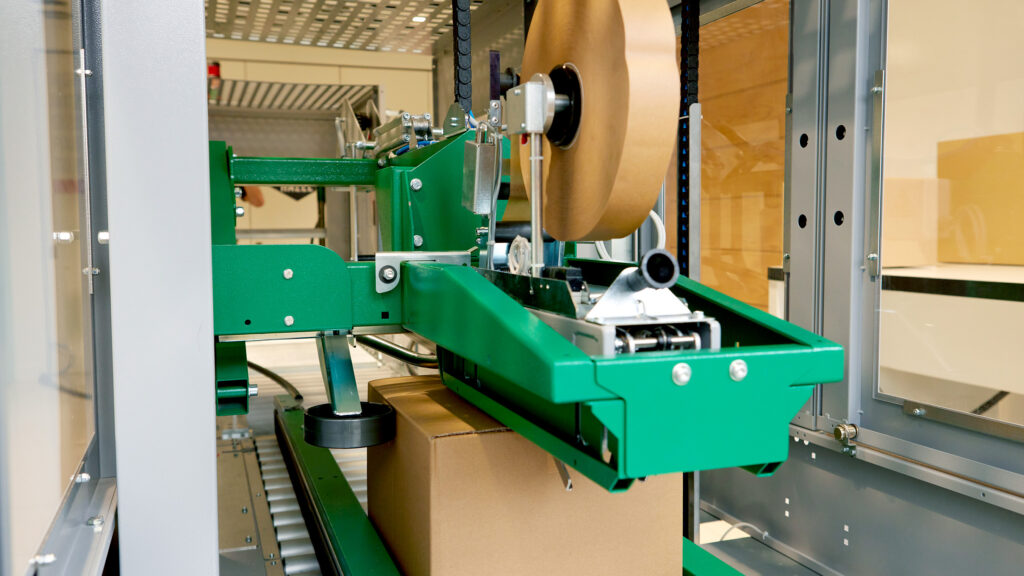

Perfect for use on production lines, choose from machines that seal the bottom of cartons or machines that can seal either the top or bottom of cartons. The height and width settings can be adjusted using the handle to match the size of the box you’re sealing. Faster than using manual or electric gummed paper tape machines. Compatible with 50 – 100 mm tape width.

Paper tape is recyclable in both B2B and B2C environments and doesn’t need to be separated from the carton. This increases recycling uptake and

makes it quicker and easier. When switching from plastic to paper, gummed paper tape has the added advantage of bonding to cartons naturally. This means one strip of tape is needed, reducing cost and waste whilst improving carton presentation.