Perfect for use with our machinery and equipment, our strapping range includes steel, polypropylene and polyester options.

It includes grades made from recycled materials and is a great solution for helping products to remain stable during transportation, and avoid damages.

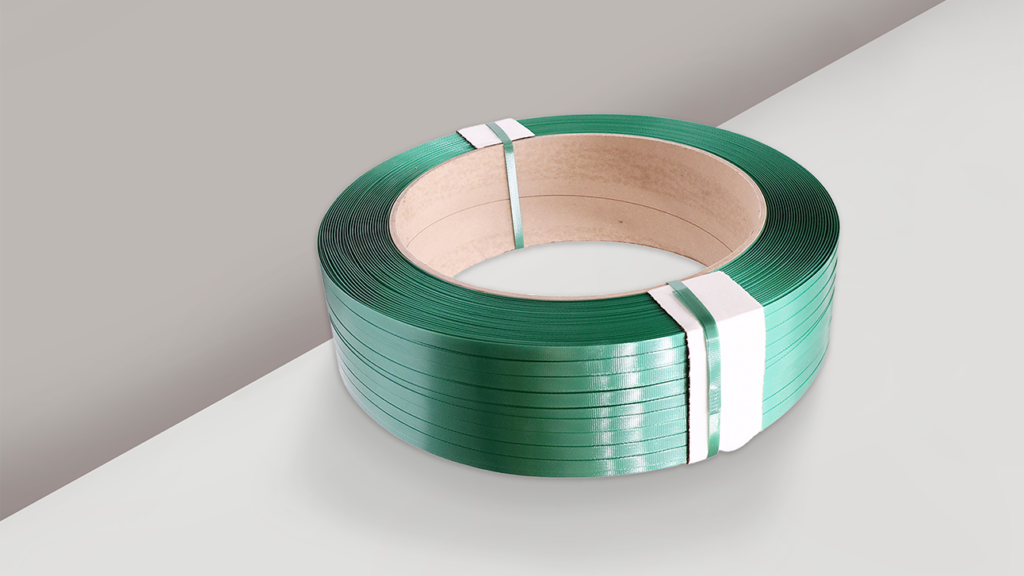

Extruded polyester strapping is strong, durable and commonly used instead of steel strapping. It’s more elastic than steel, less likely to break under pressure and easier to use. Polyester strapping is usually applied with a friction weld strapping tool.

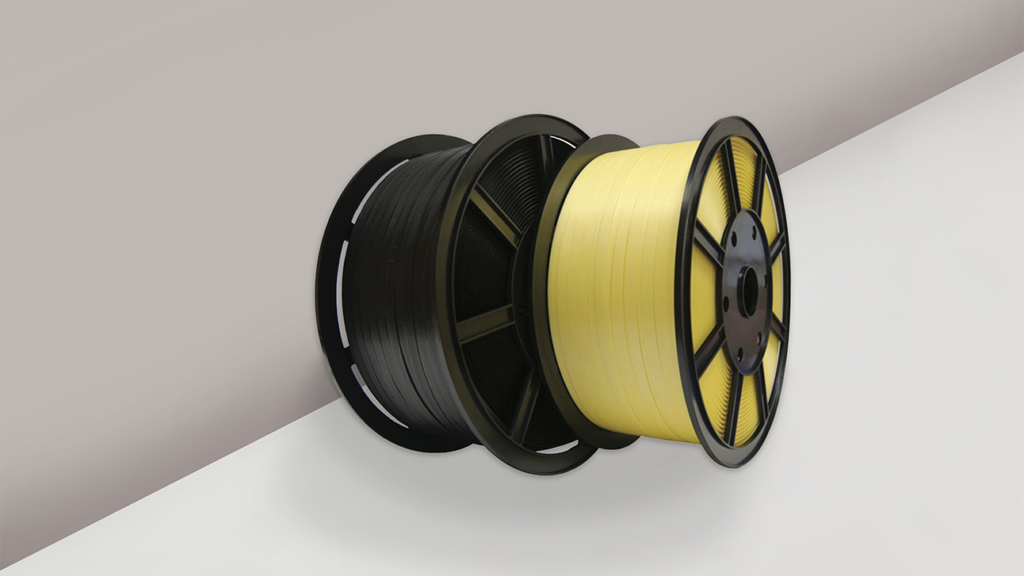

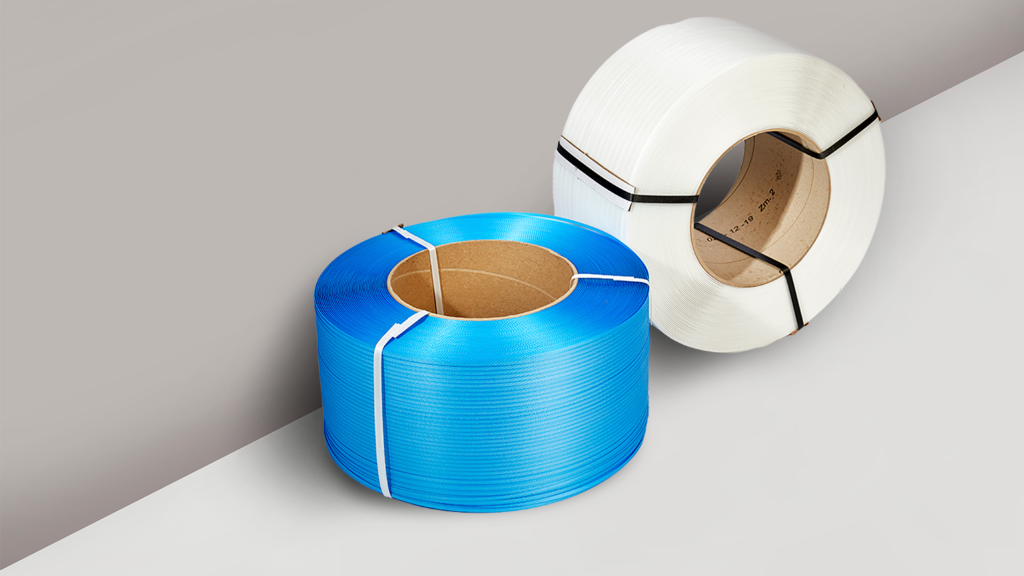

Ideal for strengthening pallets and making parcels more secure, polypropylene strapping is easy to apply and has high elasticity. This plastic reel strapping is applied by hand and should be used with a dispenser. Polypropylene strapping is most commonly used for securing palletised goods or bundling leaflets.

This machine strapping with a cardboard core is reliable, dust-free and works perfectly in most types of semi-automatic and automatic strapping machines. It’s usually applied to cartons and packages but can also be used in bundling and load securing applications. It’s low cost, simple to use and can be easily recycled.

Corded woven polyester is as strong as extruded polyester but it’s softer, so is kinder to your product and your hands. It has the strength to deal with heavy loads so can be used as an alternative to steel strapping. It’s great for strapping timber, building products, furniture and scaffolding boards. Use with steel buckles for optimum strength.

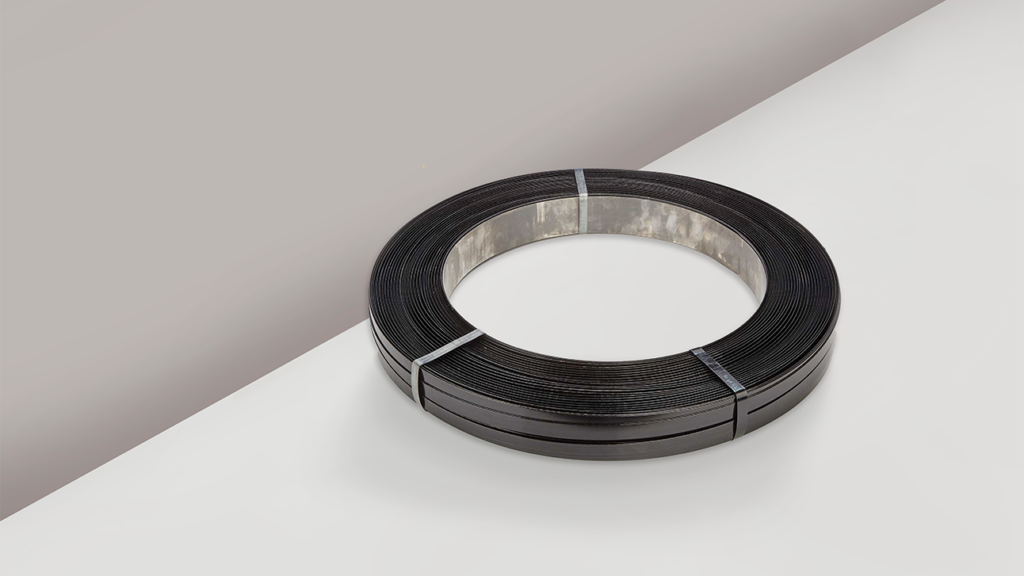

Although steel strapping has largely been replaced by polyester, it’s still available for the applications which require it. Steel strapping is available mill wound (oscillated wound) or ribbon wound, and in regular or high tensile grades.