Reducing greenhouse gas (GHG) emissions is essential in order to reduce the threat of climate change. Climate change refers to long-term shifts in temperatures and weather patterns. Such shifts can be natural, due to changes in the sun’s activity or large volcanic eruptions. But since the 1800s, human activities have been the main driver of climate change, primarily due to the burning of fossil fuels like coal, oil and gas.

Currently, 70% of global GHG emissions are directly linked with the extraction, transportation and processing of raw materials. In addition, Landfills contribute 1.9% to global GHG emissions, emphasising the environmental impact of inefficient waste disposal practices. Addressing these sources is crucial for effectively curbing the overall impact of human-induced climate change.

The Paris Agreement, adopted in 2015 and signed by 196 nation states, is a landmark global treaty aimed at combating climate change. Nations commit to limiting global warming to well below 2 degrees Celsius, with efforts to restrict the increase to 1.5 degrees Celsius. The agreement is a collaborative effort to mitigate climate change impacts, foster resilience, and transition to a sustainable, low-carbon future.

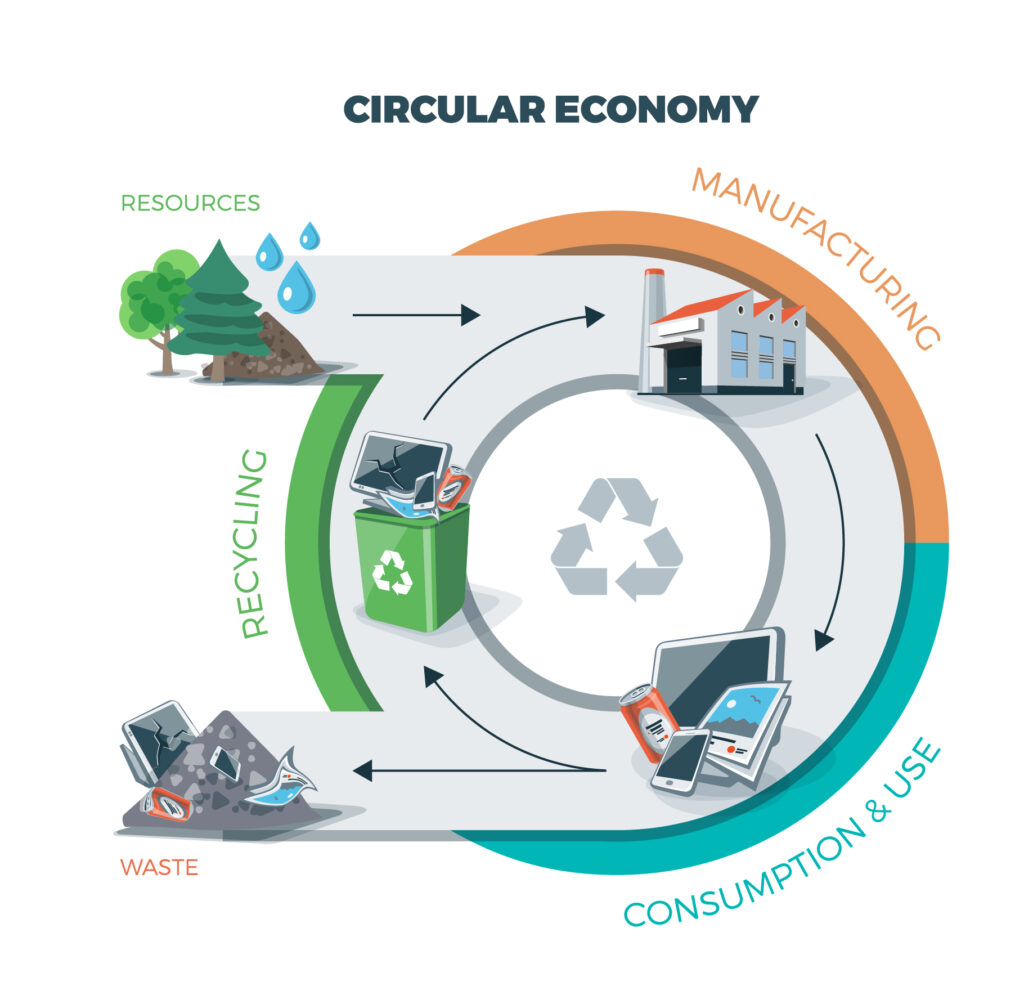

According to a 2019 European Union study, 91% of the global economy operates within a linear system. In this linear system, raw materials are extracted, processed into products, and eventually discarded as waste. Products are generally not used to their full potential and are destined to be thrown away.

It is a polluting system, that degrades natural resources, drives climate change, and contributes to biodiversity loss. Our current trajectory within a linear economy is alarming, with a predicted 3-6 degrees global temperature increase by 2050. However, adoption of a circular economy could allow us to keep global temperature below 2 degrees, as targeted by the Paris Agreement.

Circularity refers to the concept of designing, producing, consuming, and disposing of goods and services in a way that minimises waste and maximises the continual use of resources. It is a key principle of the circular economy, which aims to move away from the traditional linear economic model.

The circular economy seeks to create a closed-loop system where products, materials, and resources are kept in use for as long as possible, and waste and pollution are minimised. The transition to a more circular economy requires change throughout the entire supply chain, including product design, new business models, advances in waste management, and changes to consumer behaviour. The move to a circular economy will bring environmental, financial, and social benefits.

Post-industrial recycling involves reclaiming and reusing materials discarded during manufacturing processes. This practice minimises waste and conserves resources within industrial sectors. On the other hand, post-consumer recycling focuses on collecting and recycling materials from products at the end of their life cycle, diverting them from landfills and incineration.

Both post-industrial and post-consumer recycling contribute to the circular economy, reducing environmental impact and promoting sustainability by reintegrating materials into the production cycle, either within industries or after consumer use.

Closed loop recycling is a key concept within the circular economy framework. In a closed loop system, materials from products at the end of their life cycle are collected, processed, and recycled to create new products of similar or equal value. Recycling of PET bottles is an example of a closed loop recycling process since they can be recycled back into bottles with little degradation of the original material. Additionally, closed-loop recycling encompasses the practice of returning products to the companies or industries of their origin, allowing for their reuse or refurbishment without substantial material loss; an example of this is battery take back schemes.

However, achieving closed-loop recycling can prove challenging for certain materials, such as LDPE film. This is because it is difficult to avoid property degradation during the recycling process. Several factors contribute to this degradation, including thermal and mechanical stress, contamination-induced loss of purity, and the breaking of polymer chains, resulting in diminished strength and flexibility. It has been reported that only 2% of plastic waste is currently recycled through closed loop systems.

Open-loop recycling, sometimes referred to as down-cycling, is when materials are recycled and utilised to manufacture a different product than the one they were originally recovered from. An example includes the manufacturing of textiles from PET bottles. Open-loop recycling is often connected with the deterioration of the material properties.

Open-loop recycling is a step towards sustainability, but it does not fully capture the circular economy’s ideal of maintaining materials at their highest value. However, it still contributes to reducing overall waste and conserving resources compared to a linear economy.

Despite the current recycling system predominantly consisting of open-loop practices, it is notable that the UK GHG Conversion Factors exclusively presents carbon footprint data for materials derived from closed-loop recycling. This illustrates the data it is not representative of current composition of the waste stream.

| Raw Materials | Open-Loop | Closed-Loop | |

| Material | kg CO2e | kg CO2e | kg CO2e |

| Plastics: HDPE | 3,255.93 | 2,346.69 | |

| Plastics: LDPE and LLDPE (incl. forming) | 2,586.73 | 1,793.30 | |

| Plastics: PET (incl. forming) | 4,018.48 | 3,121.34 | |

| Plastics: PP (incl. forming) | 3,090.82 | 2,537.39 |

The UK has implemented multiple policies and initiatives to promote circularity, including, the Waste and Resources Strategy (2018) which sets strategic long-term ambitions to reduce waste and make more efficient use of raw materials.

In addition, the UK published the UK’s Circular Economy Package, in 2020, which outlines the steps and measures needed to transform the EU economy to become more circular, where materials are recycled, waste is prevented, and extraction of raw materials is minimised, increasing the duration of a product’s useful life.

Furthermore, the UK Plastic Packaging Tax, made effective from April 2022, aims to reduce single-use plastic by taxing plastic packaging that contains less than 30% recycled content, encouraging the use of recycled materials, promoting a shift toward more sustainable packaging practices.

Moreover, in 2022 the UK government proposed an Extended Producer Responsibility (EPR) scheme to make producers financially responsible for the entire lifecycle of their products, encouraging them to design products with recycling in mind in order to reduce modulated fees. This has been criticised as complex and poorly communicated and has been delayed until 2025.

Despite the implementation of multiple legislations, DEFRA has been criticised for its delay in delivering impactful initiatives; with the UK missing its 2020 recycling target after nearly a decade of stalled recycling rates.

To develop successful closed-loop systems, it’s crucial for companies to actively participate in collective efforts, be transparent through accurate and detailed data sharing, and maintain continuity in their commitments.

Technical integrity and honesty is vitally important as more often general or greenwashed terminology is being used to inaccurately describe what activities are actually occurring. The term “closing the loop” for example, is used regularly by industry bodies, businesses, media outlets and other organisations in relation to new or developing recycling schemes. Currently this is primarily a buzz term for what is predominantly open-loop recycling. The actual implementation of closed-loop systems is far less adopted and bridging this gap requires engagement across industry, ensuring companies make meaningful contributions to the development of new and pioneering waste management processes.

The need for robust partnerships becomes even more evident where governmental legislation falls short in delivering sustainable initiatives. Therefore, proactive collaboration across the supply chain is essential for companies to play a significant and effective role in shaping sustainable closed-loop frameworks in the future. End-users, distributors, manufacturers and subject matter experts must come together to maximise their joint expertise and capabilities. Engaging with these partners is crucial for navigating complexities at scale as the future of sustainable packaging for large enterprises lies in these collaborative efforts.

It is clear that the closed-loop recycling paradigm offers a huge opportunity for large-scale businesses to revolutionise their packaging strategies, integrating both environmental and economic efficiency but wider collaborations with experts and specialists are essential to successful implementation and continued success. Successfully adopting closed-loop systems will position those businesses with a competitive advantage through a commitment to responsible and forward-thinking packaging practices. Identifying opportunities for closed-loop recycling is quickly becoming a strategic imperative.